mini excavator safety Learn how to safely operate an excavator by avoiding common mistakes and hazards. Find out what not to do before, during, and after using the equipment, such as carrying passengers, swinging over trucks, or digging underneath the machine.

Learn how the width of a mini digger influences its functionality, manoeuvrability and performance. Compare different types and sizes of mini diggers and their uses in various projects.

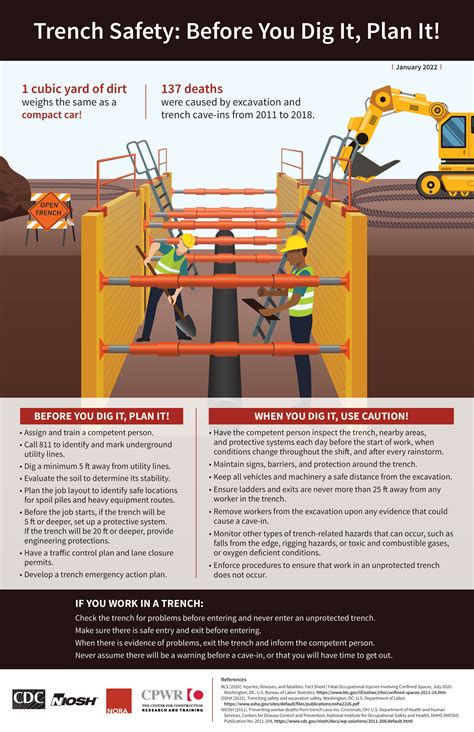

0 · safety requirements for excavation work

1 · safety guidelines for excavation

2 · osha trenching and excavation fact sheet

3 · greatest danger associated with excavations

4 · excavator safety procedure

5 · excavator safety checklist

6 · excavation safety for workers

7 · dangers posed by excavations

The Rhinox grading beam is a heavy-duty excavator attachment which is ideal for landscapers .

This guide will provide valuable mini excavator safety tips. They will help you .Learn how to safely operate an excavator by avoiding common mistakes and hazards. Find out . This guide covers everything about mini excavator safety, and the dos and . Below are a few essential mini excavator safety tips to follow on the job site, to keep your operators safe and your project on track. 1. Wear the Proper Personal Protective Equipment. The right personal protective equipment (PPE) helps ensure operator safety.

This guide will provide valuable mini excavator safety tips. They will help you prevent accidents and show your workers how to use the vehicle safely. By covering what to do before, during and after the operation of a mini excavator, you can ensure the .

Learn how to safely operate an excavator by avoiding common mistakes and hazards. Find out what not to do before, during, and after using the equipment, such as carrying passengers, swinging over trucks, or digging underneath the machine. This guide covers everything about mini excavator safety, and the dos and don’ts. Answers, what preventive measures are needed, how to operate a mini excavator safely, and tips for post-usage care.Like any heavy equipment, your mini excavator requires careful operation to minimize the risk of accidents and injuries. The potential dangers of incorrect usage include rollovers, cave-ins, electrocution from contacting power lines, collisions with other machines and .It's essential to follow mini excavator safety protocols before, during and after operation. Learn fundamental tips to prevent excavator accidents here.

All safety devices, including horns, lights, guards and shields, fire extinguishers, glass, and wipers; Engine and hydraulic fluid levels; Boom, stick (or dipper), and bucket; All controls needed for proper function; Check for hydraulic leaks, loose bolts, and cracked welds.Safely operating your Cat ® mini excavator is essential. All Cat 302.7–303.5 Mini Excavators come with a number of safety features to help keep you and your jobsite safe. Consult your Operation and Maintenance Manual for further mini excavator safety . This blog will outline the key steps for preparing your mini excavator, from pre-startup inspections to post-operation maintenance, ensuring smooth performance and maximizing the machine’s longevity. 1. Pre-Startup Inspection: Ensuring Safety and Stability By focusing on these top safety tips, operators can significantly reduce the risk of accidents and create a safer working environment when using mini excavators. Remember, safety should always be the top priority in your operations.

60 skid steer mulcher

Below are a few essential mini excavator safety tips to follow on the job site, to keep your operators safe and your project on track. 1. Wear the Proper Personal Protective Equipment. The right personal protective equipment (PPE) helps ensure operator safety. This guide will provide valuable mini excavator safety tips. They will help you prevent accidents and show your workers how to use the vehicle safely. By covering what to do before, during and after the operation of a mini excavator, you can ensure the .Learn how to safely operate an excavator by avoiding common mistakes and hazards. Find out what not to do before, during, and after using the equipment, such as carrying passengers, swinging over trucks, or digging underneath the machine.

This guide covers everything about mini excavator safety, and the dos and don’ts. Answers, what preventive measures are needed, how to operate a mini excavator safely, and tips for post-usage care.Like any heavy equipment, your mini excavator requires careful operation to minimize the risk of accidents and injuries. The potential dangers of incorrect usage include rollovers, cave-ins, electrocution from contacting power lines, collisions with other machines and .It's essential to follow mini excavator safety protocols before, during and after operation. Learn fundamental tips to prevent excavator accidents here.

All safety devices, including horns, lights, guards and shields, fire extinguishers, glass, and wipers; Engine and hydraulic fluid levels; Boom, stick (or dipper), and bucket; All controls needed for proper function; Check for hydraulic leaks, loose bolts, and cracked welds.

Safely operating your Cat ® mini excavator is essential. All Cat 302.7–303.5 Mini Excavators come with a number of safety features to help keep you and your jobsite safe. Consult your Operation and Maintenance Manual for further mini excavator safety . This blog will outline the key steps for preparing your mini excavator, from pre-startup inspections to post-operation maintenance, ensuring smooth performance and maximizing the machine’s longevity. 1. Pre-Startup Inspection: Ensuring Safety and Stability

safety requirements for excavation work

safety guidelines for excavation

6 lug skid steer bolt pattern

Replace the bucket teeth and the side cutters when the tooth points or the side cutters are worn. Page 220 MAINTENANCE WHEN REQUIRED 5. Remove the tooth point (2).

mini excavator safety|excavation safety for workers